Phosphine Resistance: Genetics and Strength of Resistance

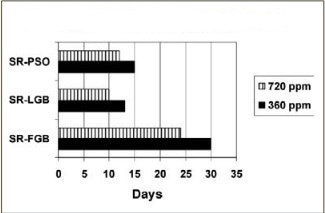

After 70 years of inadequate fumigation practices involving poorly sealed structures, repeated fumigations and low gas concentrations, phosphine resistant insects are showing up more frequently all across the world. At the 12th International Fumigants & Pheromones Conference, Dr. Manoj Nayak and Dr. David Schlipalius, from the Queensland Department of Agriculture, Forestry and Fisheries in Australia, presented how genetics affect the strength of resistance and why phosphine resistant insects are so difficult to control. Resistance to phosphine is caused by small changes in specific genes which allow insects to survive phosphine concentrations that would normally kill wild type insects (insects with no resistance to phosphine). Genes resistant to phosphine are called rph1 and rph2. These genes get their name from the “r” in resistant and the “ph” in phosphine. If an insect possess either rph1 or rph2 it will have weak resistance. Weak resistant insects can be 4-25 times more resistant to phosphine than wild type insects. If an insect possess both rph1 and rph2 it will have strong resistance. Strong resistant insects can be > 250-400 times more resistant to phosphine than wild type insects. Different species of stored product pests have different strengths of resistance. Recently, strong resistant rusty grain beetles (Cryptolestes sp.) showed the highest strength of resistance and were found to be 1,300 times more resistant to phosphine. These strong resistant insects threaten the use of phosphine fumigants and need to be managed properly to ensure the future use of phosphine products. In their 2010 journal “Developing strategies to manage highly phosphine resistant populations of flat grain beetles in large bulk storages in Australia,” Dr. Manoj Nayak and others determined it would take a fumigation at 68°F (20°C) of 360 ppm for 30 days to control all strong resistant rusty grain beetles. That is a full month under fumigation! Their graph indicates the time to population extinction at 68°F (20°C) at two different phosphine concentrations for strong resistant Psocids (book lice) (SR-PSO), strong resistant lesser grain borers (SR-LGB), and strong resistant flat grain beetles (SR-FGB)

Phosphine Resistance: A World View

Phosphine resistance has been detected all across the world. A global survey in 1976 found 33/82 countries had phosphine resistant insects. In India every storage site tested had 76-94% of insects carrying phosphine resistance. Worldwide, there are currently 12 species of stored product pests that have shown resistance to phosphine fumigants. At the 12th International Fumigants & Pheromones Conference, Dr. Manoj Nayak and Dr. David Schlipalius, from the Queensland Department of Agriculture, Forestry and Fisheries in Australia, presented an update on worldwide trends and what Australia has done to help control phosphine resistant insects. Thirty years ago Australia developed a nationwide monitoring program to determine the trends of resistance frequency in insect populations and now lead the world in phosphine resistance research. As a result, they have longer time and higher temperature requirements for using phosphine. They require a 7-day fumigation if the grain temperature is above 77°F (25°C), 10 day fumigation if the grain is 59-77°F (15-25°C), and suggest not fumigating if temperatures are below 59°F (15°C). Australia also requires pressure testing on silos prior to fumigation to determine if the silo is structurally tight enough to fumigate. Pressure testing is a federal requirement when fumigating grain silos and is called the Australian Standard (AS2628).

This standard states that the silo to be fumigated must perform a 5 minute half-life pressure test. This ensures that a silo is gas tight and is able to hold lethal concentrations of phosphine gas for a given time to control insects at all life stages. If a silo does not pass the Australian Standard (AS2628), then the silo is considered not tight enough for an effective fumigation and is not fumigated. The map shows samples of phosphine resistant insects across Australia. You can see that there is less prevalence of strong resistant insects in the western half of Australia. This is believed to be from more structures that pass the Australian Standard AS2628. These silos are more structurally more gas tight and result in more effective fumigations.

Phosphine is an indirect toxin which means the amount of toxin within an insect increases the longer the insects are exposed to phosphine concentrations. This is in contrary to direct toxins which stay constant over time, such as the case with cyanide. Phosphine produces more and more toxic byproducts with time.

These toxic byproducts build up and kill insects by disrupting the fat metabolism process that damages the nervous system. Nerves are dependent on fat metabolism produced by mitochondria. Mitochondria are organelles in cells where the respiration process happens. During a phosphine fumigation, phosphine and oxygen are absorbed into the mitochondria and produce toxic oxygen radicals. These toxic oxygen radicals then interfere with the fat oxidation process which then amplifies and produces additional toxins within the pest. The genes resistant to phosphine affect the pathway in which phosphine kills insects. The rph1 gene is expressed in fat oxidation and the rph2 gene in oxygen radical. These two genes are genetic mutations. Insects have evolved to endure more toxic byproducts which allow them to survive higher phosphine concentrations. The effectiveness of phosphine fumigants are dependent on the insect’s ability to metabolize fat. Fat metabolism takes time, but this process can be increased with warmer temperatures. This is why phosphine becomes more toxic and effective over longer periods of time and higher temperatures.

These toxic byproducts build up and kill insects by disrupting the fat metabolism process that damages the nervous system. Nerves are dependent on fat metabolism produced by mitochondria. Mitochondria are organelles in cells where the respiration process happens. During a phosphine fumigation, phosphine and oxygen are absorbed into the mitochondria and produce toxic oxygen radicals. These toxic oxygen radicals then interfere with the fat oxidation process which then amplifies and produces additional toxins within the pest. The genes resistant to phosphine affect the pathway in which phosphine kills insects. The rph1 gene is expressed in fat oxidation and the rph2 gene in oxygen radical. These two genes are genetic mutations. Insects have evolved to endure more toxic byproducts which allow them to survive higher phosphine concentrations. The effectiveness of phosphine fumigants are dependent on the insect’s ability to metabolize fat. Fat metabolism takes time, but this process can be increased with warmer temperatures. This is why phosphine becomes more toxic and effective over longer periods of time and higher temperatures.

(fumigationzone.com)